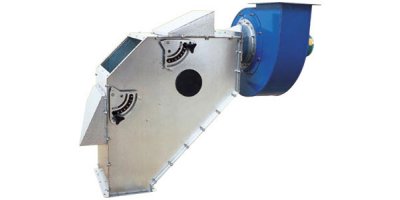

PA-I INCLINED ASPIRATION CLEANER

APPLICATION ON SILO INLET

Removes fine dust particles.

Used in almost any point of the system or processing machine.

Indispensable for grain cleaning.

Simple and fast installation.

Operating principle

The product enters by gravity and is uniformly distributed over its entire width.

The product, with a veil descent, is hit by a transverse air flow that will suck the lighter parts, which will be decanted by a cyclone or filter.

The airflow is regulated by the "false air" A.

CONSTRUCTION

- Aspiration casing in press-formed galvanized metal

- Aspiration inlet

- Air flow regulation dampers

SPECIFICATIONS

Available in various sizes and models with cleaning capacities from 30 to 120 t/h (calculated with wheat, specific weight 0.78 t/m3 - RH 14% Impurities 2%).

|

MODEL |

PA 20 I |

PA 40 I |

PA 60 I |

||

|

Capacity - t/h (densitate 0,78 t/m3) |

25 |

40 |

60 |

||

|

Motor - kW |

1,1 |

1,5 |

3 |

||

|

Lenght - mm* |

1494 |

1581 |

1847 |

||

|

Width - mm* |

527 |

600 |

697 |

||

|

Height - mm* |

1049 |

1189 |

1017 |

||

|

Weight - kg |

85 |

150 |

215 |

||

|

Volum - m3 |

0,8 |

1,1 |

1,3 |

||

OPTIONAL

- Inlet reduction cone

- Outlet reduction cone

- Electronic flow regulation

Home

Home